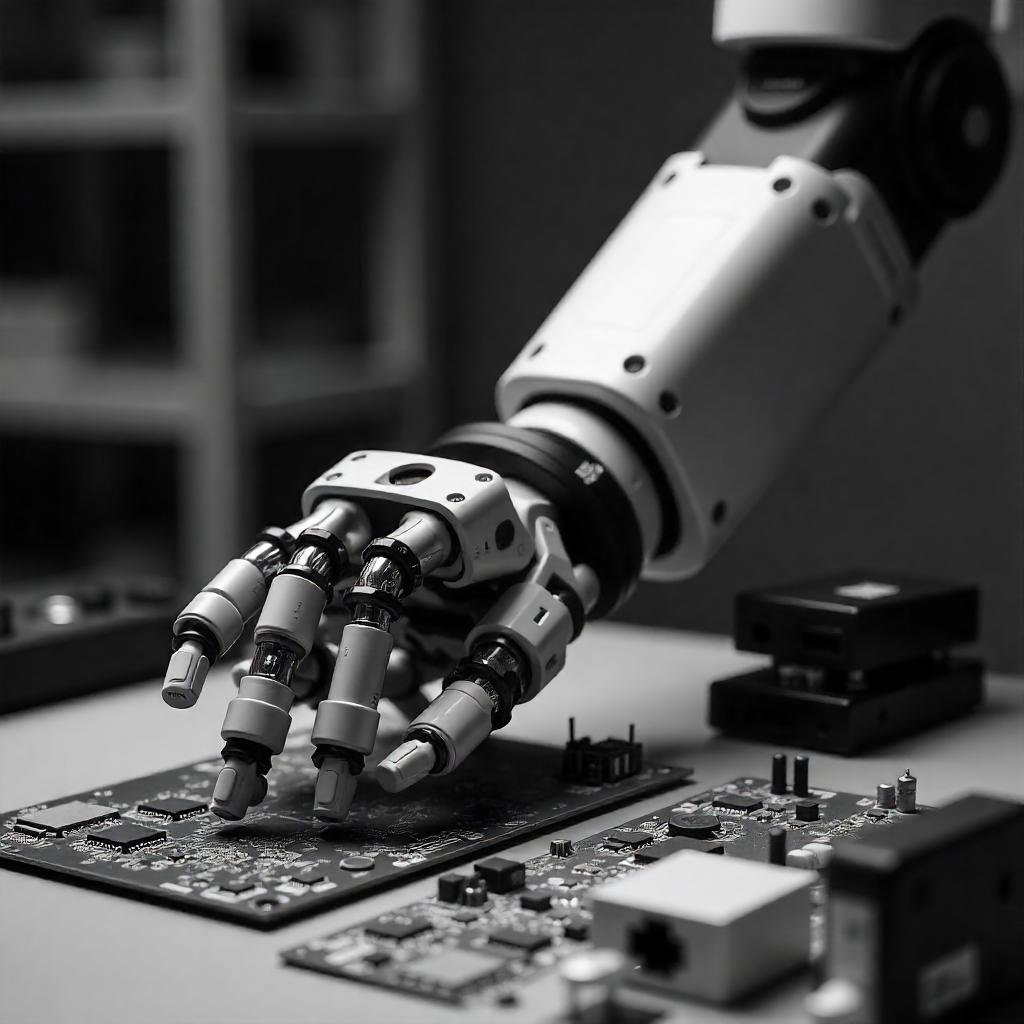

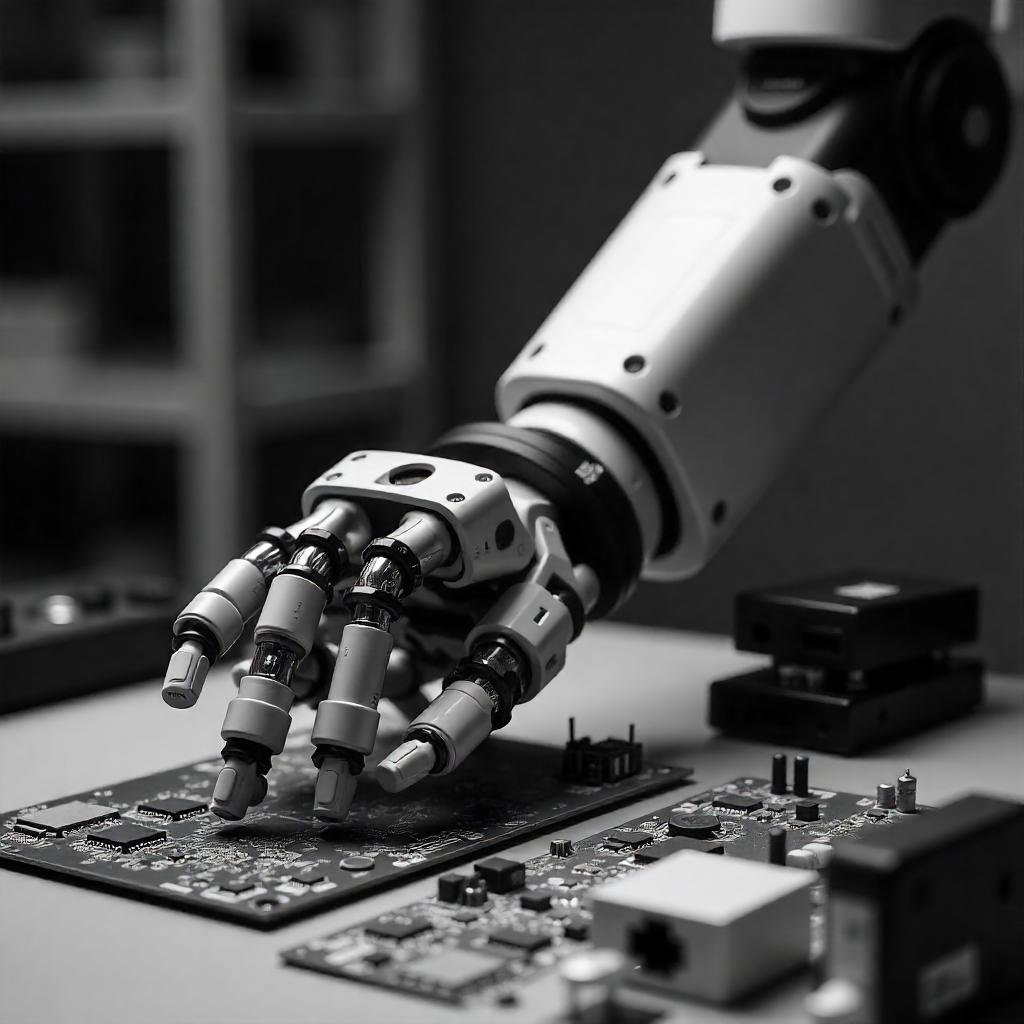

Innovating the Future with Intelligent Robotics

Vintillix is at the forefront of robotics innovation, designing and developing intelligent robotic systems that automate tasks, enhance precision, and improve efficiency across multiple industries. Our robotics solutions are engineered to seamlessly integrate with business operations, optimizing workflows and reducing operational costs.

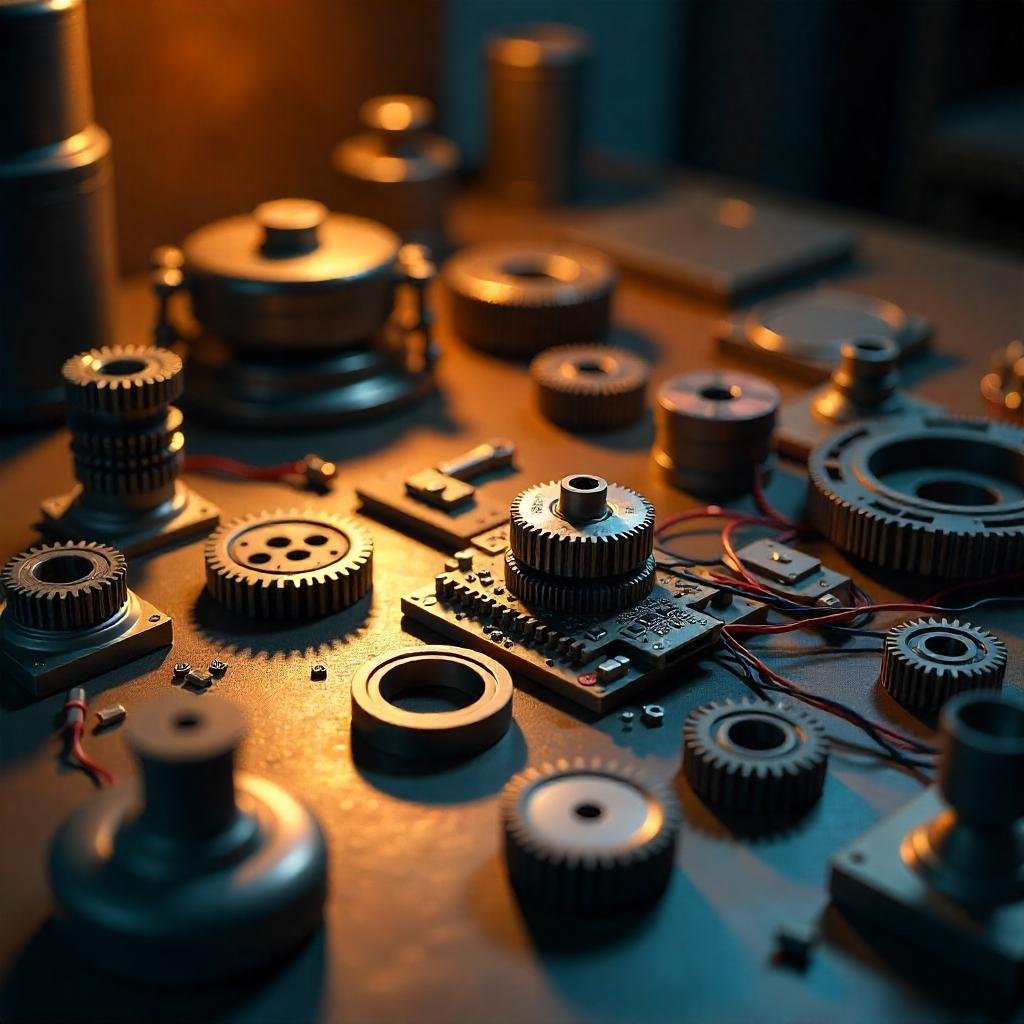

Key Features of Robotics

* Autonomous & Semi-Autonomous Systems – Capable of self-navigation and task execution with minimal human intervention.

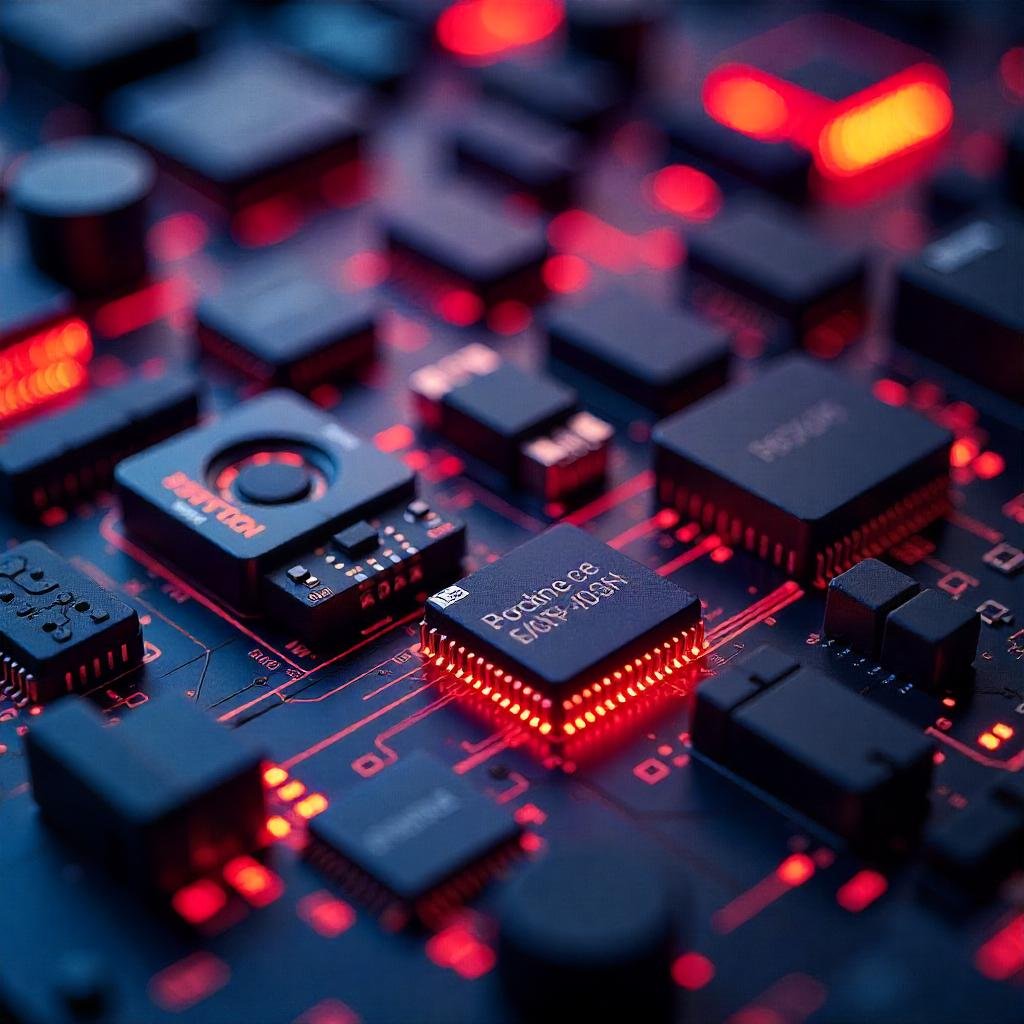

* AI-Powered Robotics – Integrating machine learning and real-time data processing for adaptive and intelligent decision-making.

* Human-Robot Collaboration – Enhancing workplace efficiency through seamless interaction between robots and human workers.

* Precision Engineering – Ensuring high accuracy in operations, from industrial automation to medical applications.

* Scalable & Customizable – Tailored robotic solutions designed to meet the specific needs of various industries.

Applications of Robotics

* Manufacturing & Industrial Automation – Smart robotic systems for assembly lines, quality control, and predictive maintenance.

* Healthcare & Medical Robotics – Robotic-assisted surgery, patient care automation, and AI-driven diagnostics.

* Logistics & Warehousing – Automated inventory management, sorting, and last-mile delivery solutions.

* Agriculture & Smart Farming – AI-powered robotic solutions for crop monitoring, irrigation, and harvesting automation.

* Security & Surveillance – Intelligent robotic patrols for real-time monitoring and threat detection.

Vintillix is committed to revolutionizing industries through cutting-edge robotics technology, paving the way for a smarter, more efficient, and highly automated future.